CORONA TREATMENT Application

Plastic has a majorly used as a barrier, a barrier from air & water i.e. it resists air or water from passing through:

Ink or water does not stay on Plastic so how do we Print on Plastic?

A thumb rule says: That the surface energy of the Plastic should be 10 points more than ink or Adhesive, than only will it bond with each other. Surface Energy (energy associated with the intermolecular forces at the interface between two media the surface energy per unit area equals the surface tension. — also called free surface energy.)

Surface Energy of Plastic is lower than that of Ink, Increase the Surface Energy of the Plastic, which should be more than Ink or the adhesive. When Plastic is passed through Corona Discharge, We call it as treated surface, i.e. the Surface Energy is increased.

Applications:

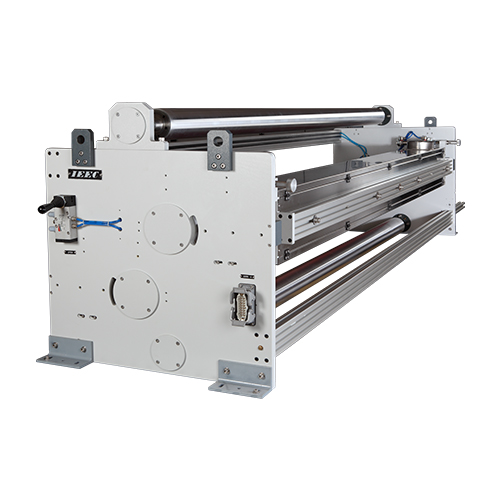

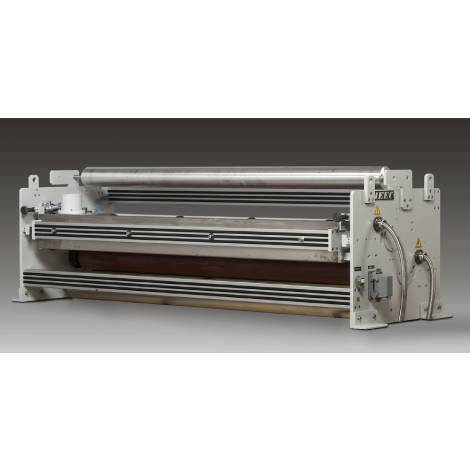

- Blown Film, Extrusion, Lamination, Pre-Printing

- Wide Web for Blown film: web width above 2.5mtrs

- For Plastic and Metallized Substrates for an application like Labels: Web Width up to 16”

- Sheets and Panels: for Web Thickness 4mm

- Plastic and Metallized Substrates used for applications like Adhesive, Lamination, Printing