CONVERTING LINES

Quality treatment of substrates at high line speeds

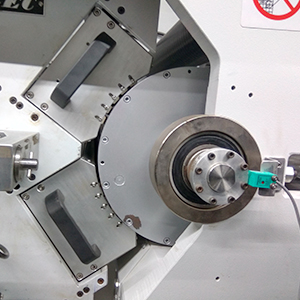

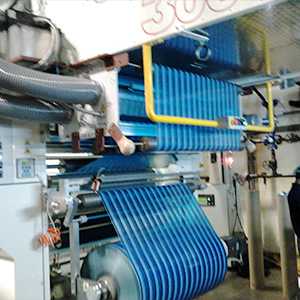

Converting applications such as Rotogravure /Flexographic printing solvent less/solvent based lamination, slitting, coating, Extrusion lamination /coating calls for treatment of verity of substrates at very high line speeds. IEEC’s RFIM Corona Treating Station comes with high definition ceramic electrodes which can treat metalized and non-metalized substrates at high line speeds.

Technical advantages include:

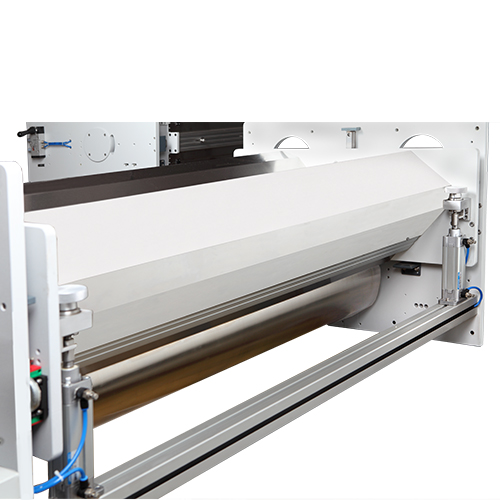

- Web width up to 2100mm

- Line speeds up to 600mpm

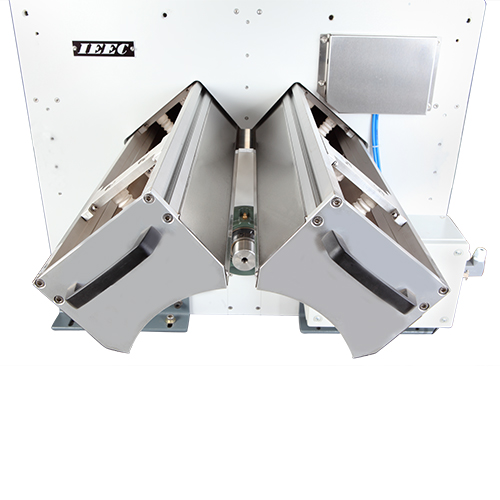

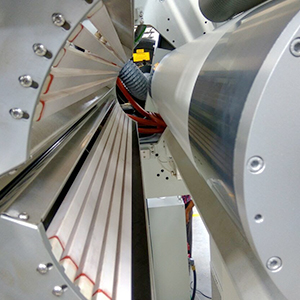

- High definition ceramic electrodes with ridge profile to ensure uniform treatment levels at high efficiency

- Corona Treater Roller made out of Aluminium

- Dynamically and statically balanced Treater Roller

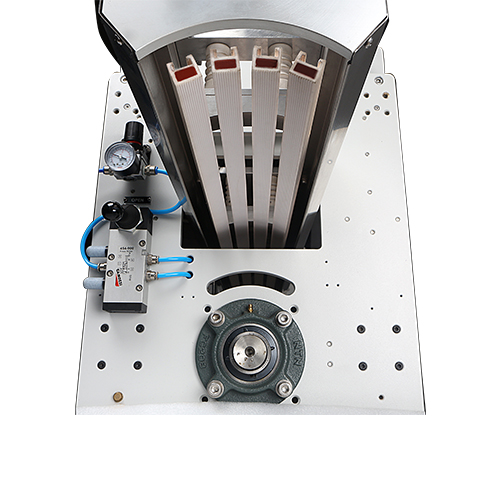

- Precise air gap adjustment during operation

- Specially-designed electrode ducts with air flow dynamics to ensure negative pressure during Ozone extraction for electrode cooling

- Vacuum switch for ensuring negative pressure

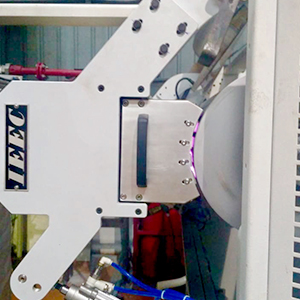

- S.S. Braided double dielectric sheathed high tension cable

- Proximity switch for zero speed sensing and closed loop feedback for auto- watt density control

- Assembly open limit switch for human safety

- Glazed ceramic insulators for rigid mounting of ceramic electrodes

- Pneumatic actuation of electrode heads for easy treading of film